1978 York Micro poptop caravan

The rebuild

As purchased, the little Micro was quite a tidy van,even after very careful inspection...but things changed!

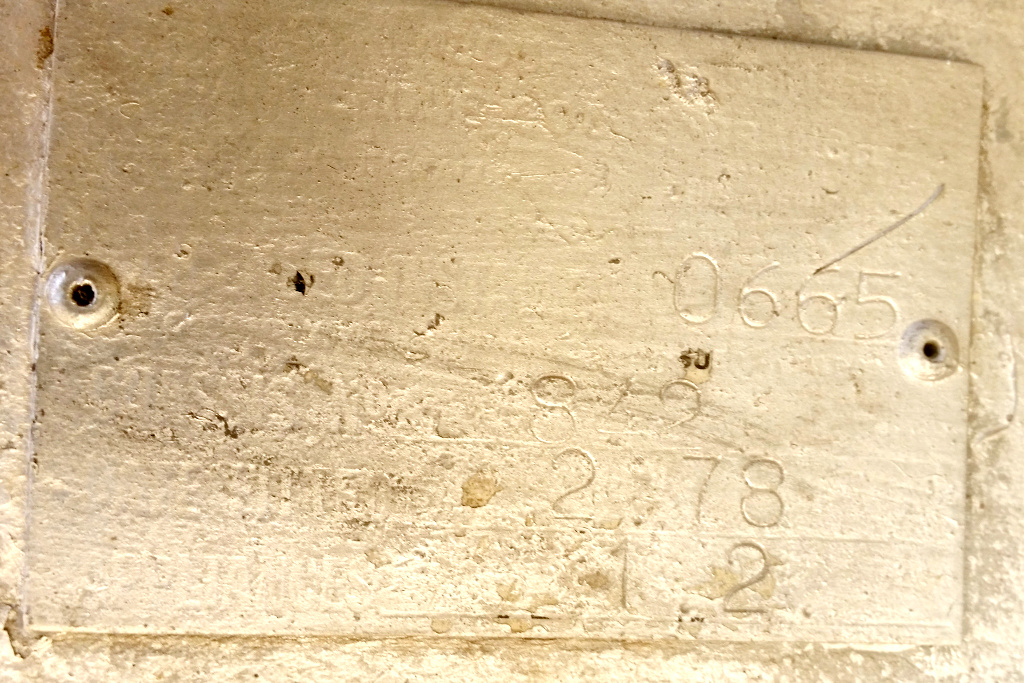

↑chassis number.

↑build plate.

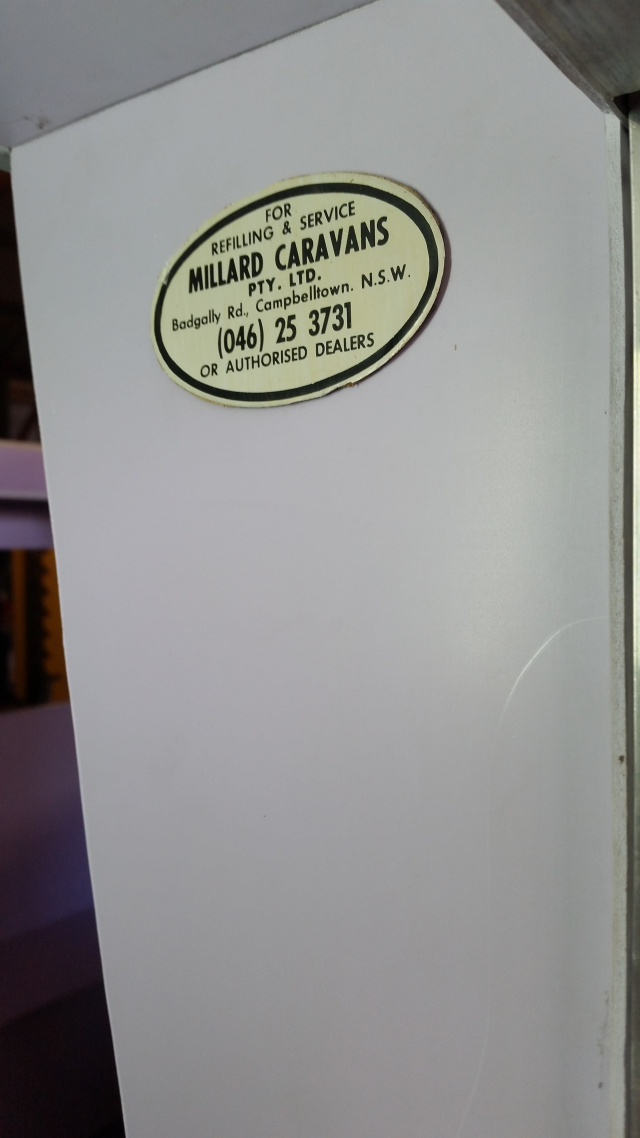

↑original sticker just

inside the door on the wardrobe wall.

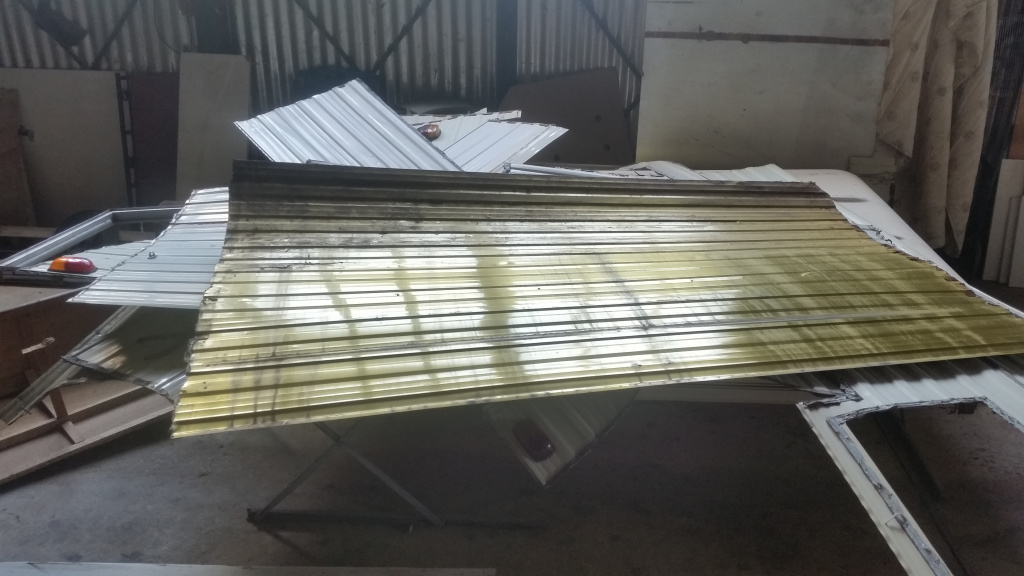

↑ The minor repairs to the

interior started to uncover things. Once the external cladding was removed

(totally necessary as stage 1, there is no other way with this sort of

construction) things started to get more serious.

↑ Basically things were

fairly good, but the edges of the plywood sections were suffering. Aluminium

frame was perfect. So, it was obvious the only way to deal with this was to

totally dismantle the van.

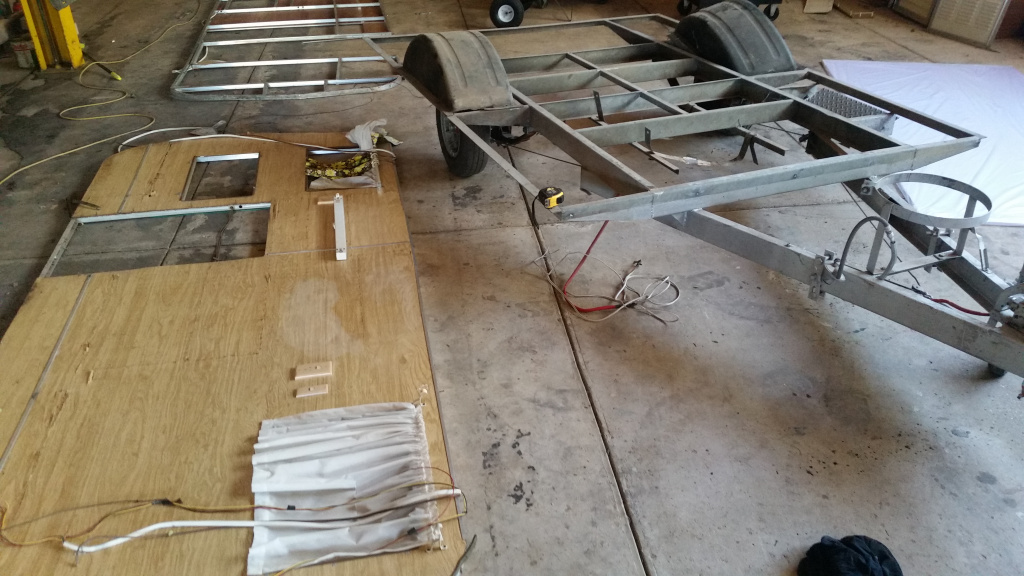

↑...so that's what

happened. All rivets drilled out, and the caravan sections dismantled.

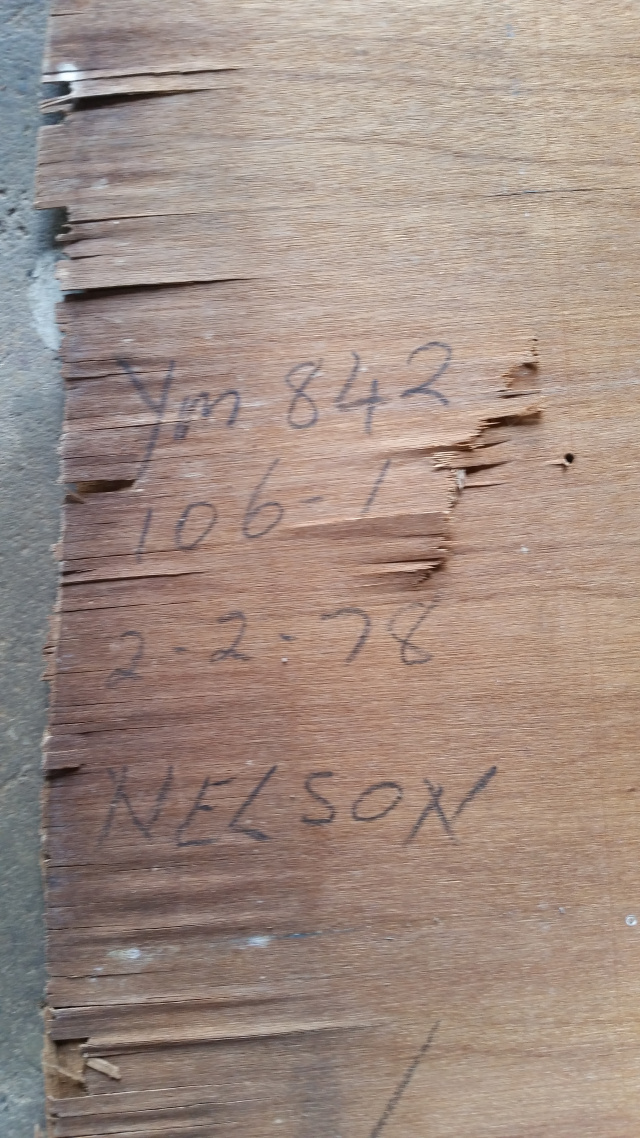

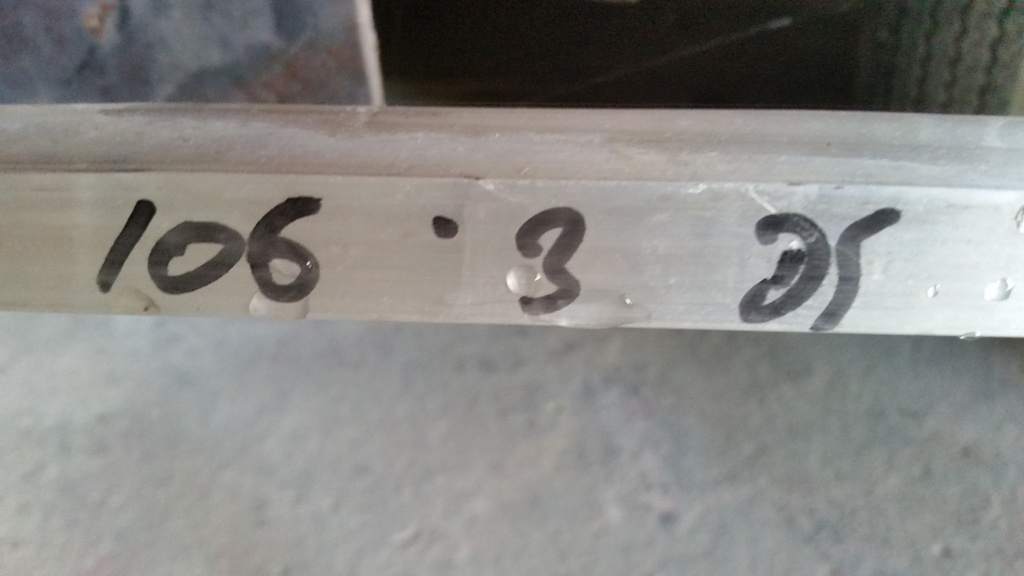

↑ No doubts about

the build date! This was on the back of the original plywood wall just in

front of the entrance door.

↑ These photos

show how the aluminium frames were pre-fabricated in the factory to suit

various floor plans, and given the approriate codes.

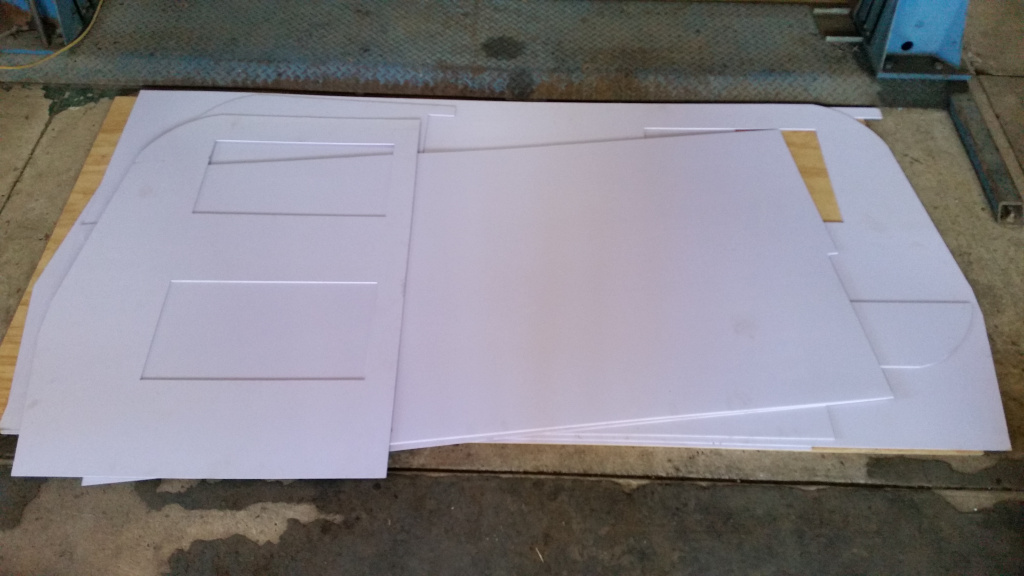

↑ After much

research, I decided to get rid of all wood-based components, which included

the 3mm plywood walls. My decision was to use largely untried PVC foam

panels, which have been used for some time in the signwriting and display

industries, but almost no use in this manner. Cost was comparable, weight

comparable, mechanical strength very close, environmental aspects better,

and definitely vastly better with moisture and related issues.

So, the purchase was made, from Panels World in Ravenhall, Melbourne, and the experiment begins! Above are some of the interior panels pre-cut from the 3mm PVC foam board after carefully tracing the designs from the 3mm plywood originals.

↑ The 3mm PVC foam lining boards have been bonded to the frames, after cutting

the sections using the original plywood as patterns. I was going to also

rivet them, using large headed rivets in the original locations, but am

presently thinking the bonding will suffice. Once fitted to the frames, the

3mm board is surprisingly 'firm', and the frame is much more rigid to

handle. I think it'll work well!

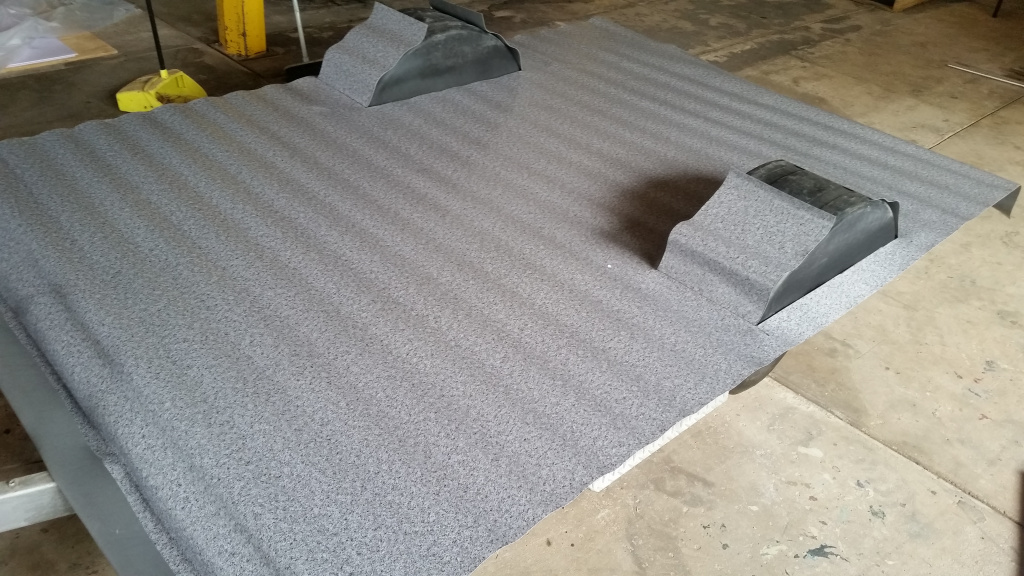

↑ The 10mm PVC foam

board in place on the floor. As this caravan will occasionally carry a few

heavy classic car parts, I was originally going to add some additional

struts to the underfloor chassis, but decided in the end to trim the

original plywood floor to chassis size and retain it underneath the PVC

floor. Going to 15mm PVC flooring would have been about as rigid as the original

10mm ply.

↑ To ensure total

waterproofness of the caravan, I scoured the materials left over from a

recent major house renovation, and selected this Sika 2-part epoxy product

(anything would have done), mixed it up, and applied it to all the joins,

and filled all the gaps around the original wheel arches which had been a

source of moisture and rubbish ingress in the past.

↑ After a sanding with

the belt sander to level everything off, a bit of matte black acrylic paint

was sprayed around the wheel arches. No real reason, as these will never be

visible, but that's what I do.

↑ 2 metre wide vinyl

floor covering was carefully measured (twice), and cut (once) and laid out

over the floor, and, as it was relatively cool and the vinyl was still

retaining its rolled-up shape, I worked on the

Cranvel digger for most of the day until

things warmed up, and the vinyl became more cooperative!

↑ Then I returned to the Micro, and carefully glued the vinyl to the PVC flooring.

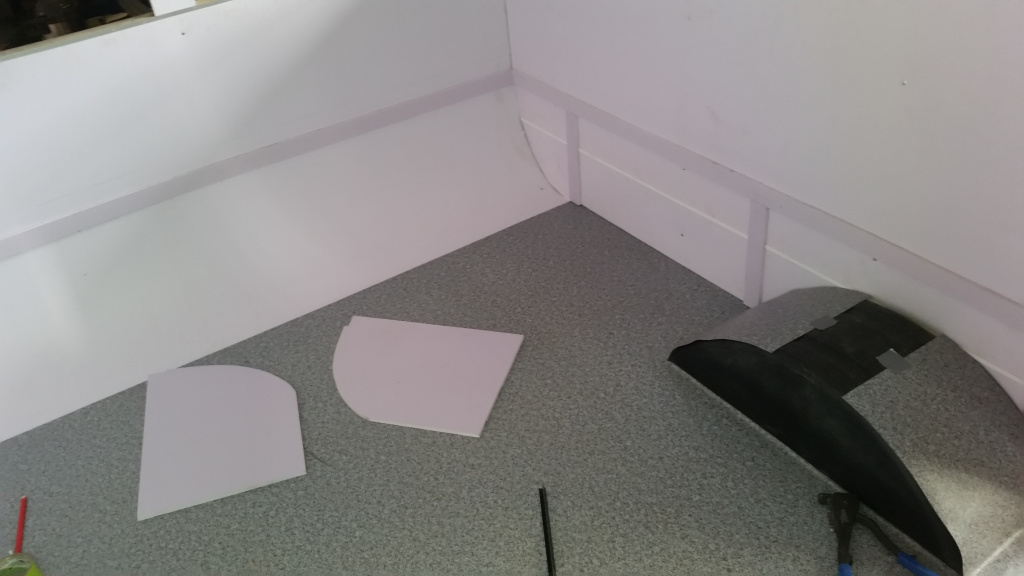

↑ Now it was time to

attach the prefabricated wall panels to the floor. First the right hand wall

and the rear window panel...

↑...then the front

panel...

↑...and then the

really complex lower end panels that start off being inside the side walls

beneath the rear window framework,...

↑...but then become

outside the frame at crucial point. You can just see the PVC 'wedges' being

held in place by clamps while the PVC glue sets. These were cut on a

bandsaw, carefully copying the timber originals. Once this sets, I'll curve

the panel over the frame and bond it to the underside of the PVC floor

panel, just as the original 3mm plywood panel was stapled to the original

10mm plywood floor. The window was temporarily riveted into place just to

ensure everything was kept as square as original. I am re-using all the

original rivet holes to ensure everything lines up to exactly as it was

assembled in the factory 45 years ago.

↑The view from the

front at this stage.

↑ Finally I get to

test the bendability of the PVC panelling, and its stiffness when curved (as

it's the only support for the external cladding at this point).

Both aspects look really good! Being PVC, I used clear PVC cement to bond the 3mm skin to the underside edge of the 10mm floor, where the original plywood version had been stapled. The jacks and clamps in this photo are holding a wooden support beam in place while the PVC cement cures.

↑ The front lower

panel is positioned, and the 'wedges' replicated on the workshop bandsaw

from the timber originals are glued and clamped in place (see next photo for

detail).

↑ This is how the

'wedges' appear after being cut on a bandsaw (exactly to the shape of the

timber originals) from 10mm PVC board, and glued to form a 20mm wedge.

Neutral cure silicone seals any possible air or water leaks.

↑ All

relatively straightforward until I came to the structure supporting the

fibreglass poptop roof. The original timber supports were still perfect, and

could have been re-used, but I was on a mission! Dimensions couldn't change

by more than a mm or so, as I will reinstall all the original, aged

cladding, using all the original rivet holes.

I finally

came up with a design that used 15mm x 30mm x 2mm rectangular aluminium

tubing to replicate the original 13mm timber struts, and also used a

'sandwich' of 10mm and 3mm PVC board to exactly match the original 13mm

wooden surround that the canvas attaches to, and the roof seals onto when

dropped.

↑ After a lot

of careful measuring, remeasuring, cutting, clamping, remeasuring and

glueing, the structure is basically in place. Dimensions are mm perfect, so

I know the roof will fit when it's eventually reunited with the van after

the old cladding is refitted. There will be absolutely no timber to rot in

this thing!

↑ I'd

been thinking a lot (generally when I should have been sleeping!) about how

to treat the interior. This had to be decided on before the outer cladding

went on, or even before I decided on the where and how of the LED 12V strip

lighting I'll install. This van is being built for a specific purpose,

primarily to tow behind my beavertail truck any time my we venture to

distant places to pick up any new vehicles or parts. It also will be used

occasionally behind a classic car attending an event that we'd prefer to

stay overnight at, so it had to be light, had to be guaranteed never to rot

(no timber at all - the galvanised chassis and aluminium frame are still

perfect after 45 years, and were the reason I chose this van), and had to

probably carry awkward objects, or parts. No kitchen needed, no overhead

cabinets, no wardrobes, no 240V power, no built-in fridge (we can simply

pack our trusty portable 12/24/240V fridge/freezer), no stove or oven (if we

really want to cook, we have ample portable camping equipment that can be

brought along), and no permanent upholstery or bedding (we have a great

inflatable camping mattress we can throw on the floor), probably no

underfloor water tank (still an option to refit, but we'd just carry

containers of water when needed). The sleepless nights came from trying to

work out the plan that left as much of the floor vacant (big enough for a

standard double camping mattress to fit), but gave as much storage as

possible for various things (but low down - I really wanted to avoid

overhead cupboards and anything else that unnecessarily jutted out into the

limited usable space). The problem, though, was that the original cupboards

were structural, giving support to the poptop side supports.

So the structural solution in the end was the slender, angled 'brackets' I made from 10mm PVC foam board, which feed the roof loads into the wall frame, just as the cabinets had, but much more rigidly. It took a lot of working out, and a few dry runs, to get these firmly installed using both PVC welding cement and stainless steel screws driven in from the exterior so they are invisible. It worked a treat!

↑ The precut

(from 10mm PVC board) skeleton that will support the front 'bench seat' that

is primarily both structural and offering plenty of storage (the 'lid' will

be removable). A similar design will apply at the rear, but in a 'U' shaped

plan that will incorporate the wheel arches on the sides.

↑ Finally

the time has come to get serious, and start installing the

seating/storage/stiffening units. First stage is to very carefully measure

everything, mark it in pencil (easy to remove), and then mask up so I can

accurately and neatly apply the PVC primer and cement when installing the

wall 'rails' to support the lids/tops/seats, whatever you want to call them.

PVC cement is ruthless in its time demands, giving almost no time to apply

adhesive and fit the item, so careful masking means I can go like a madman.

I hold the rails in place carefully for about 10 minutes before relaxing the

pressure, and will then screw with stainless steel screws from the outside

of the wall panelling for extra support.

↑ Sounds

easy, but doing it solo was an absolute pain! A lot of improvising was

needed to replicate a human 'helper' by positioning various props to hold

things in place on the other side of the wall while the cement set,

effectively 'welding' the PVC together. So far, so good!

↑ After

buying 3 more sheets of 10mm PVC foam board, and a couple of days carefully

cutting on the Triton saw bench, and lots of careful gluing and screwing,

the perimeter seating/storage units are all in place. As the board is so

light, I decided not to hinge the tops, but make them removable (simply

locking into position with tabs carefully located underneath), as I may

sometimes want the storage units without a top (awkward materials or car

parts I may be picking up), and leaving them behind is a lot better than

lids flapping about on hinges.

↑ I went to a bit

of trouble to save this original sticker on the side of the wardrobe at the

entrance. I coudn't remove the vinyl from the backing without risking

damage, so carefully cut around it with a sharp hobby knife and retained the

top layer of the original plywood...

↑ ...and put it

in the same location on the structural strut that was put in place to take

the roof loads the wardrobe previously took.

↑ While I

retrieved the fibreglass poptop from the workshop rafters, using a forklift,

I was careful to remove anything that might get damaged if things went

curly! So the caravan was pushed outside into daylight for the first time in

a long time, giving the chance for some well-lit photos.

↑ Once back

safely to the floor, the poptop was turned upside down to remove the

original plywood ceiling. This was still in pretty good condition, but I was

resolute in my plan to delete all plywood!

↑ Worth showing

the original vents that are crucial in preventing rotting of the integral

structural timbers of the poptop, and the plywood ceiling. After cleaning

up, these will definitely be reinstated. So many 'restorers' don't

understand the importance of ventilation to deal with inevitable

condensation.

↑ The upturned

fibreglass poptop with the ceiling removed. All in perfect condition, thanks

to the vents (above). After a small solar panel is installed, the necessary

wiring will be fitted before a new 3mm PVC foam board ceiling is fitted,

using the carefully-removed plywood originals as patterns.

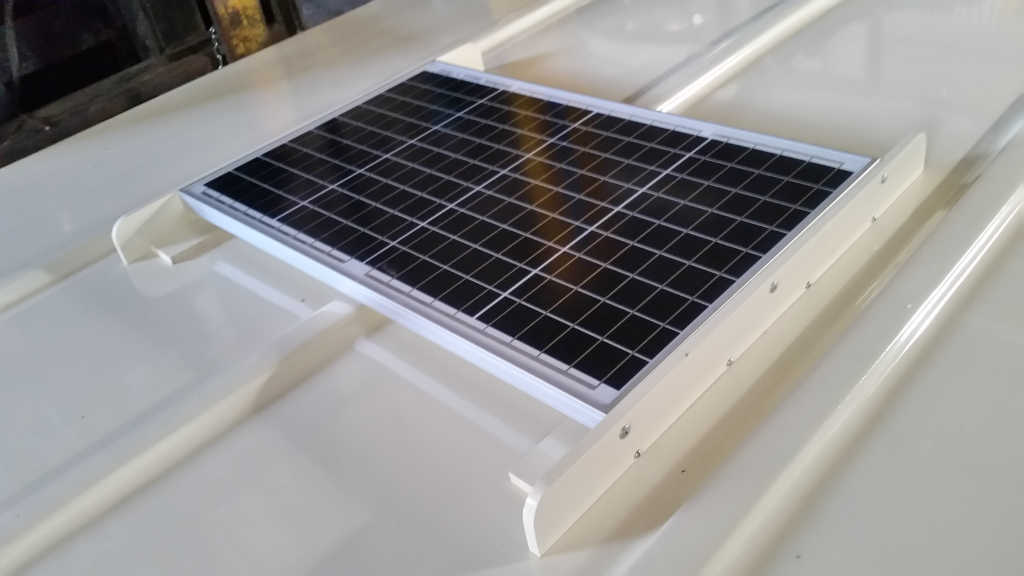

↑ Trial

fitting the 30W solar panel, using custom-made mounting (using offcuts of

the 10mm PVC foam board) that replicates the roof profile while allowing

adequate ventilation under the panel. A modest 15AH Lithium battery will

supply the modest power needs for the LED lighting and small water pump.

↑ I made up a

battery box from 10mm PVC foam board offcuts to tightly hold the LiFePO4

battery, using the dimensions given by the supplier. Luckily, they were

accurate, and it fitted like a glove.

↑ Here is the

battery and 10A solar controller, installed for testing. Wiring will be

tidied up, now that tests on a nice sunny day show it works perfectly!

Switch panel (far to near) is 1) on/off for external Anderson connector for

external, portable solar panel or 12V accessory we wish to power from

outside (fridge, lighting, whatever), 2) master on/off, 3) water pump (see

below), then a voltage indicator and a 10A circuit breaker.

↑ Lighting wiring

installed.

↑ light

switches just inside the door. Top is indoor lighting master, bottom is

outdoor (original fitting will be converted to 12V LED only).

↑ Each end

of the caravan has a warm white exterior grade, waterproof LED 5050 strip

light, controlled by a nearby rocker switch (so either end can be switched

on or off, after the main light switch is switched on).

↑ Front and

back lighting respectively. LED strips simply face up and bounce the light

off the white PVC panelling for nice, even lighting.

↑ This shows

the input for the poptop-mounted solar panel via curly cord and

European-spec 'lighter socket', and the double USB power outlet on each side

of the caravan.

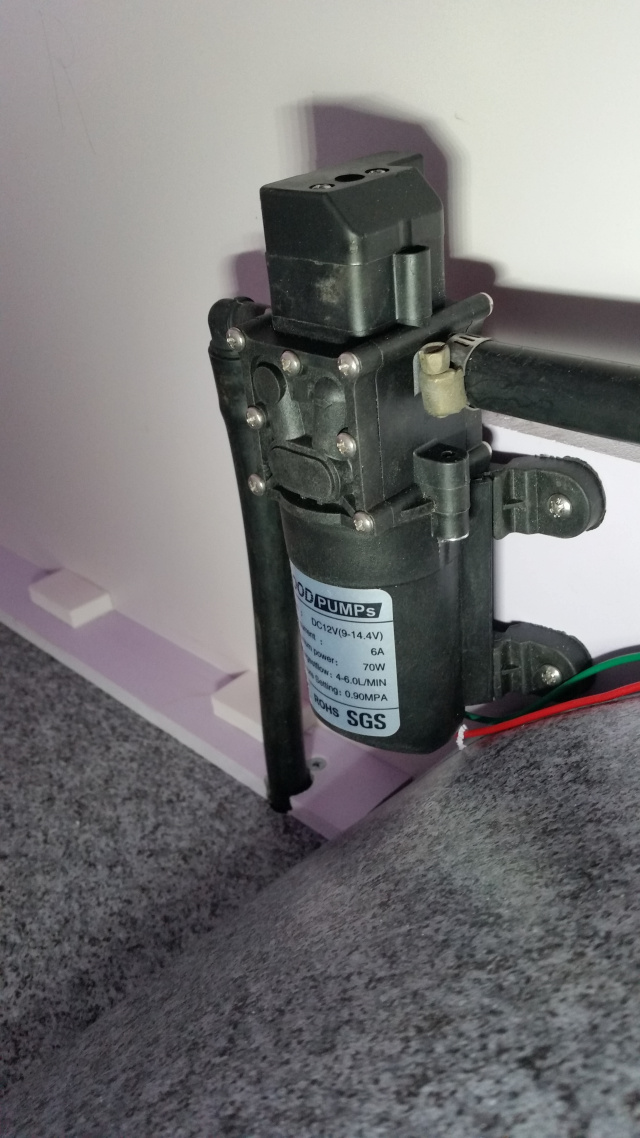

↑ Initially I wasn't

going to refit the original water tank, but the problem of the ugly hole in

the cladding where the water inlet was situated, and a bit of thought about

water for general purposes, made me decide to refit the tank, and fit an

inboard automatic pump that would supply a tap mounted on the

A-frame/drawbar. Raiding my parts stores, I decided to utilise a vintage

brass tap and fabricate a flared copper pipe etc. Quickly polished it all up

on the bench, and sprayed some clear lacquer over it. Just a silly, but fun

thing that beat putting on a new plastic tap...

↑ I had

planned to simply put the exterior cladding back on as it was. Aged, a few

small dents here and there, etc. But as the rest of the rebuild was going so

incredibly well, I decided to spend even more time, and a bit more money,

just to get the outside nice and fresh again too. As I progressed, I knew

I'd made the right decision. Millard had used a hard putty on the exterior

edges, which was harder than concrete after 45 years! The only way to remove

it thoroughly was to initially, laboriously chip the bulk of it away with a

sharp chisel, and then finish with an angle grinder fitted with a poly

wheel. That stripped the original finish as well, which required etch

priming of the exposed aluminium.

↑

Some hours were then spent with a 'caramel wheel' removing all the original

vinyl pinstripes and various stickers, including the original dealer's

stickers.

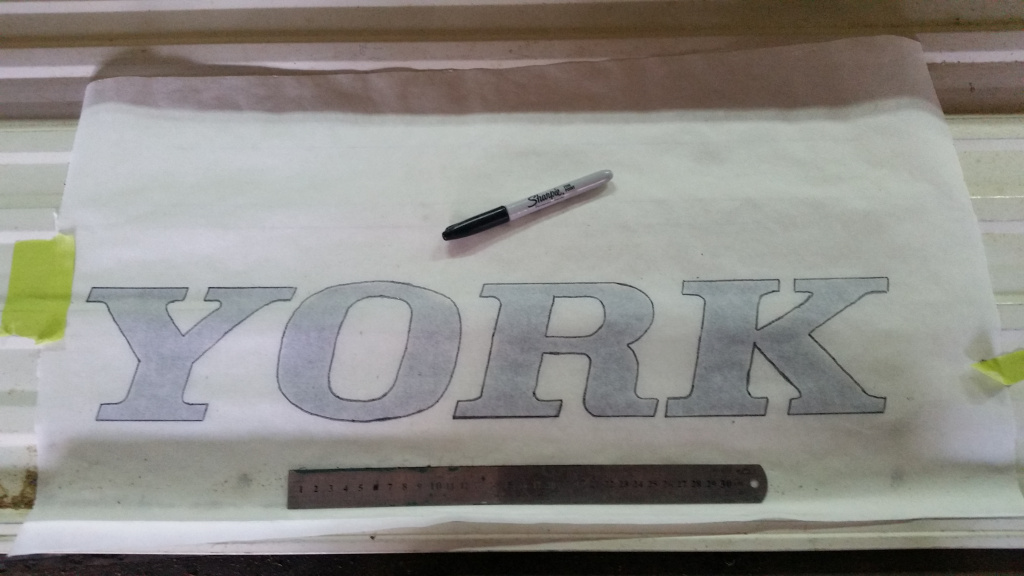

↑ Just in

case the vinyl lettering I ordered online, using the closest font I could

find (see below), I carefully traced the original YORK stickers before I

removed them with the caramel wheel (what an amazing tool!)

↑ This is

the closest font (the bottom italic one) after hours of browsing Dafont. Not

exact, but close. If I'm not happy with them, I'll cut my own by hand, using

my traced patterns.

↑ The

fibreglass poptop after a high-pressure cleaning to remove all ingrained

dirt, before spraying a primer/surfacer.

↑ all

original panels were carefully sanded and sprayed with primer/surfacer, with

these panels requiring subtle hammer-and-dolly rectification of minor dents,

before they all sat out in the sun to cure, while the caravan itself was

pushed out of the workshop into the sun to test the newly-installed solar

charging system. It performed perfectly!

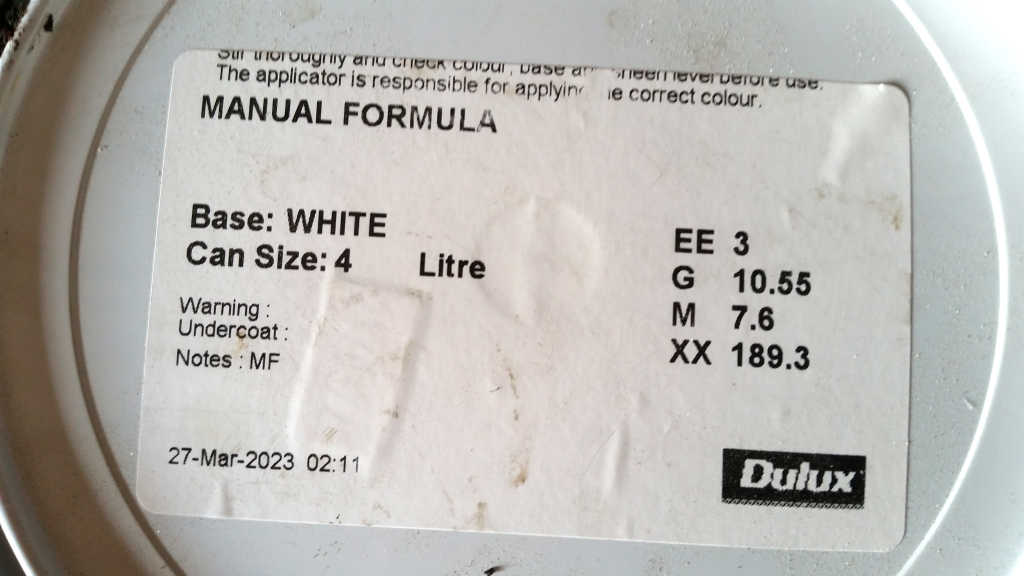

↑ I then

the topcoats, using Dulux Super Enamel High Gloss after a lot of

thought and research. These vans have a particular Millard colour that I

find really appealing, and I wanted to replicate exactly. I had a Dulux

spectrometer mix done by the very professional folk at Dulux Ballarat, using

a part of a door panel that had never seen the light of day (interior, and

covered). The match finally arrived at by the perfectionist doing the mixing

was totally invisible when applied to the sample panel. The formula in this

pic is exactly what you will need if trying to accurately restore your York

or Millard from this period.

↑

After a bit of time away, busy with other projects while the newly sprayed

original panels had a chance to thoroughly cure, I came back to the job

today, finishing the wiring inside the wall cavity area, and then

positioning the end panels (using original rivet holes so everything lined

up) and built upwards to the crucial poptop roof area. Everything lined up

beautifully, do all my careful measurement, careful cutting and assembly is

paying off. Applied the original pattern triple pinstriping to the poptop,

which will soon have its solar panel, wiring, and new PVC foam board ceiling

fitted before being carefully placed back onto the caravan. Thank goodness

for my forklift for this exacting task.

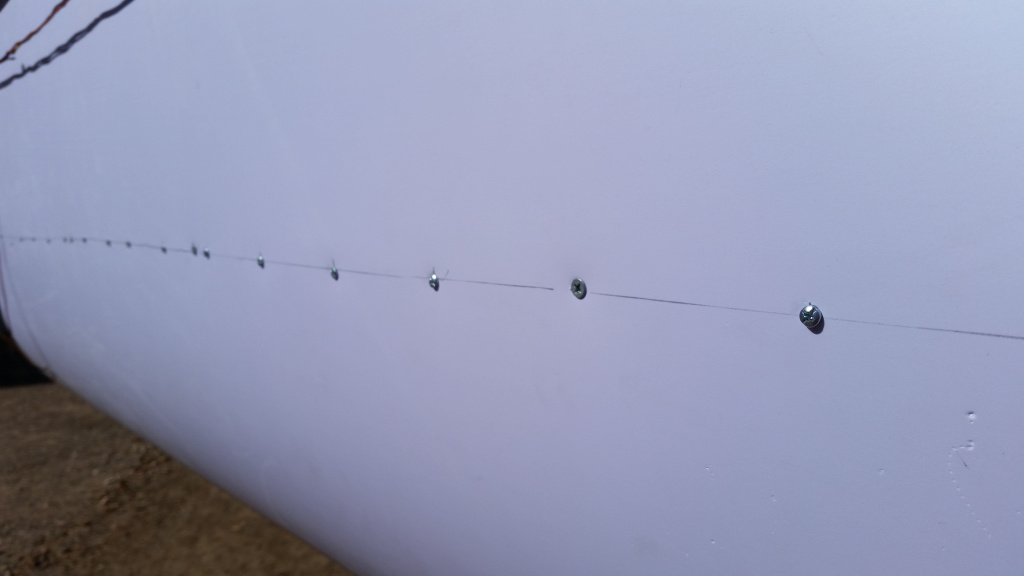

↑ All

exterior panels (original, and resprayed in the original colour) are now

loosely riveted in place, using the original holes. Everything lines up

perfectly, so all good! Things are being kept 'loose' until the final full

rivet and seal, as I want access to the wall cavities until the last minute

in case of any changes to wiring, etc. The windows I thought were going to

be a quick clean and fit, but I have spent the last 2 days, dawn to dusk,

disassembling, repairing, re-rivetting, acid cleaning, nylon wheel brushing,

undoing and properly fixing previous owner and 'repairer' repairs, and then

finally refitting the original glass with new seals. Oh yes, a few

expletives were used to good effect as well.

↑

Now that it's totally waterproof (for ever - guaranteed!) I didn't even

bother pushing it back into the workshop for the night. Exterior still needs

minor finishing off, stripes painted on the sides, YORK and Micro decals

made and fitted and a new padded vinyl stone guard sewn up and fitted on the

front. Interior just needs some edge trimming around the newly refitted

widows and door, new flyscreens made and fitted, and a tiny bit of

electrical work to finish off when the bits arrive in the mail. It was nice

to see the Lithium Iron Phosphate battery charging up nicely in the glorious

outdoor winter sun today (powering the LED lights for the dusk photo).

↑

The 10A curly cord I made up to connect the poptop (and its 40W solar panel)

to the caravan internal controller and 15Ah LiFePO4 battery, which plugs

either end into neat, European-style 'cigarette lighter' connections (much

neater and much more reliable contact than the usual style here in

Australia), mounted inside the ceiling and on the top of the adjacent wall.

Neat and effective.

↑

The 'utilities' area under the right hand enclosed bench seat, using the

wheel arch area that is virtually useless for storage. Clockwise from top

left is the battery, its switch panel, the solar controller, incoming 240V

AC supply with 16A RCBO in an external grade waterproof housing, which feeds

just a double (and dual pole) powerpoint out of view on the bottom left, and

the 12V water pump (bottom right) which supplies the outdoor tap on the

drawbar from the original underfloor tank.

↑

The original window winders all (except one) had the knobs missing. The

price of replacements was ludicrous, and they were probably not anywhere

near the quality of the originals, which, other than the fact they'd lost

their knobs after 45 years, were actually a good quality metal with nice

grub screws. So, I thought laterally, and purchased a set of nice plastic

beads for a few dollars on eBay. Then it was just a matter of drilling the

hole a bit bigger to suit the stainless steel, domed-head allen key screws I

had in the workshop, filing a flat area on top of the bead so the domed

screw head effectively continued the curvature of the bead, and simply

assembling the two onto the original handle. I only used 5, so might

eventually find a use for the other beads!

↑ stripes (in

the colour of the most likely towing vehicle, the

Isuzu Beavertail), and decals carefully replicating the originals really

set it off!

↑ the usual

'Kelly St Classics' detail treatment.

↑ a few

interior pics in daylight, with poptop up and interior LEDs on.

↑ and a few in

near darkness (dusk) in the workshop. These also show the blockout window

coverings I made from 3mm PVC foam board offcuts. Simple and effective (more

details below).

↑ the

window blockouts sit (on their bottom edge) in simple brackets I fabricated,

and then simply snap into place on the top using 10mm diameter (1mm thick)

neodymium magnets bonded to both the covers and the frames. Very positive,

very quick.

↑ I

decided to use simple magnetic catches to ensure the seat bench tops stayed

down while travelling (4 on each top), which give a nice, instant, positive

latching effect.

↑

Because the interior PVC wall panelling and exterior original aluminium

cladding were carefully installed on the aluminium frame to be totally

water-proof, and therefore virtually air proof, any condensation forming on

the inside of the cladding during cold conditions would be trapped, and

would doubtless cause problems with mould etc. The simple - only - solution

was to introduce ventilation into the wall cavity, which I did internally

rather than externally so that dust, small insects etc wouldn't enter the

cavity from outside. Ten 50mm circular vents were installed (three on each

side wall, and two in each end wall) which look neat and will prevent

condensation moisture building up. (In fact, many problems people put down

to leaks are actually caused by condensation, rather than leaks.)

↑

A couple of detail shots - the drawbar mounted external tap, and the

original RVMAA badge repainted and reatt5ached in its original rivet holes.

↑

With huge thanks to Rob Frost, General Manager at

Noel's Caravans

in Pooraka, South Australia, where this van was sold new, replacement decals

were posted to me to provide the finishing touch to the restoration!

↑

Just 480kg empty over the weighbridge!

And that's it for the rebuild! Click here to return to the caravan's main page.